Qatar Breaks Ground on World's Largest 3D-Printed School

Qatar Foundation has begun construction on a pioneering school complex at Qatar Science and Technology Park (QSTP), set to become the world's largest 3D-printed school project. This initiative highlights the increasing adoption of advanced construction technologies in the MENA region.

Project Details

Located in Qatar Foundation's Education City at Qatar Science and Technology Park (QSTP), this ambitious project will construct a large-scale school complex using state-of-the-art 3D concrete printing technology. The goal is to deliver a modern educational facility while showcasing the benefits of additive manufacturing for large public infrastructure. Construction is being carried out in phases, with the first phase expected to be completed by the end of 2025.

Leveraging 3D Printing Technology

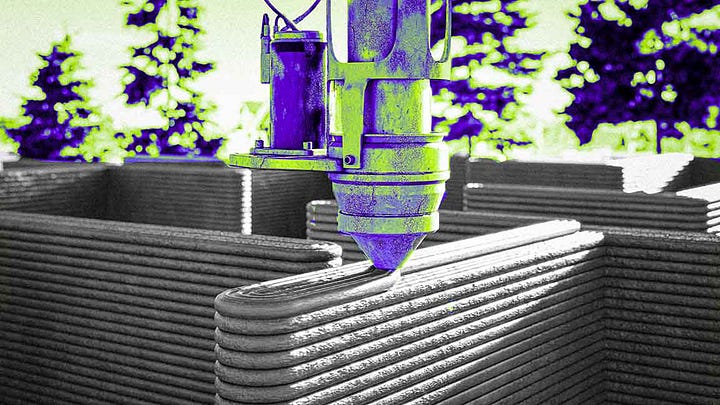

The heart of the project is the use of large-scale 3D concrete printing, where robotic systems extrude concrete layer by layer from digital designs. This approach offers several advantages over traditional methods:

Reduced Waste: Minimizes material use compared to conventional building.

Faster Construction: Significantly decreases build times.

Lower Environmental Impact: Reduces CO₂ emissions and enables the use of sustainable materials.

The technology provider for the 3D printing process is GEFEN Technologies (GEFEN).

Implications for Construction & Sustainability

This project marks a major step forward for construction in the MENA region. By undertaking the world's largest 3D-printed school, Qatar is demonstrating how innovative technologies can be used for large-scale public buildings. It serves as a case study for sustainable construction practices, supporting global efforts to reduce the environmental footprint of the built environment. The potential use of sustainable concrete mixes, possibly involving Q-Cycle, further underscores its commitment to sustainability.

Key Collaborators

The project is led by Qatar Foundation, a non-profit organization supporting education, science, and community development, in partnership with several key entities:

AlJaber Engineering: Project contractor.

GEFEN Technologies: 3D printing technology provider.

Q-Cycle: Involved, suggesting a focus on sustainable materials.

About GEFEN Technologies

GEFEN Technologies is the technology provider behind the 3D printing process for this record-breaking project. Their involvement is crucial for implementing large-scale additive manufacturing techniques required for this structure.

The Road Ahead

With the first phase set to finish by the end of 2025, the project will offer valuable insights into scaling 3D printing for complex public buildings. Its success could pave the way for broader adoption of this technology in the MENA region and beyond, transforming construction timelines and sustainability standards for future developments.

Source: Fast Company Middle East